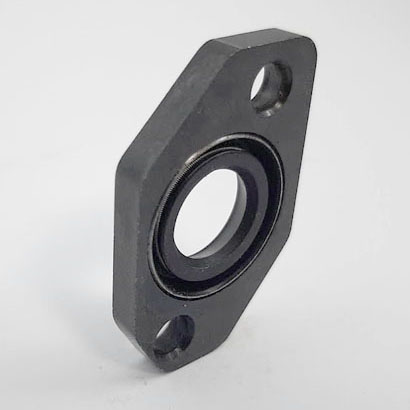

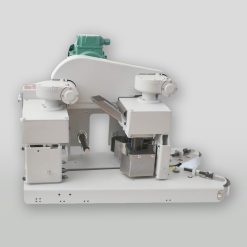

Flexible seals such as the fischbein 15104, often made of rubber or similar materials, are fitted around shafts to create a tight seal against the housing. A properly sealed shaft ensures that oil remains within the sewing head, keeping critical parts lubricated for smooth operation and preventing excessive wear. It blocks dust, dirt, and other external particles from entering the machine, preventing potential damage and malfunctions.A well-maintained seal shaft contributes to consistent stitch quality by ensuring proper lubrication and preventing thread breakage or inconsistent tension.

Maintenance:

- Regular Inspection: The seal shaft and seals should be inspected regularly for signs of wear or damage.

- Replacement: If the seals become worn or compromised, they should be promptly replaced to maintain the seal shaft’s integrity.

- Cleaning: Keeping the area around the seal shaft clean can help prevent contaminants from accumulating and potentially degrading the seals.

In essence, the seal shaft plays a vital role in the Empress 100 sewing head’s durability and performance by ensuring proper lubrication, preventing contamination, and contributing to consistent stitch quality.